Printed Corrugated Boxes (20)

Corrugated box Manufacturing

The Comprehensive Guide to Corrugated Boxes and Their Manufacturing Excellence

Imagine a world where every product you purchase arrives at your doorstep in perfect condition, thanks to the unsung hero of shipping and packaging – the corrugated box. Renowned for its strength, versatility, and sustainability, corrugated boxes have become the foundation of packaging needs across various industries. From the delicious pizza that you crave to the latest gadget you ordered online, corrugated boxes protect and preserve goods, ensuring they reach consumers just as intended. But what makes these boxes such an indispensable part of modern commerce, and how are they crafted to perfection?

The Structural Ingenuity Behind Corrugated Boxes

At the heart of corrugated boxes lies a unique construction process that combines durability with lightweight design. Layers of kraft paper are ingeniously bonded together with a fluted, wavy middle layer, providing cushioning and structural integrity. This innovative design not only withstands the rigors of shipping but also offers excellent protection against impacts, moisture, and temperature variations. Whether you require packaging for delicate baklava or a secure e-commerce box, the customizable nature of corrugated materials ensures that there's a solution tailored to every need.

- Outstanding Durability and Load-Bearing Capacity

- Enhanced Product Safety During Transit

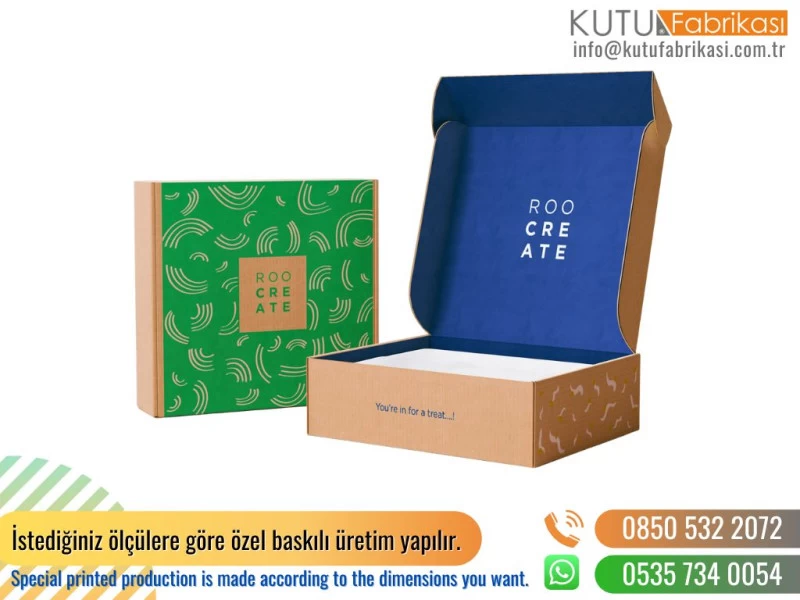

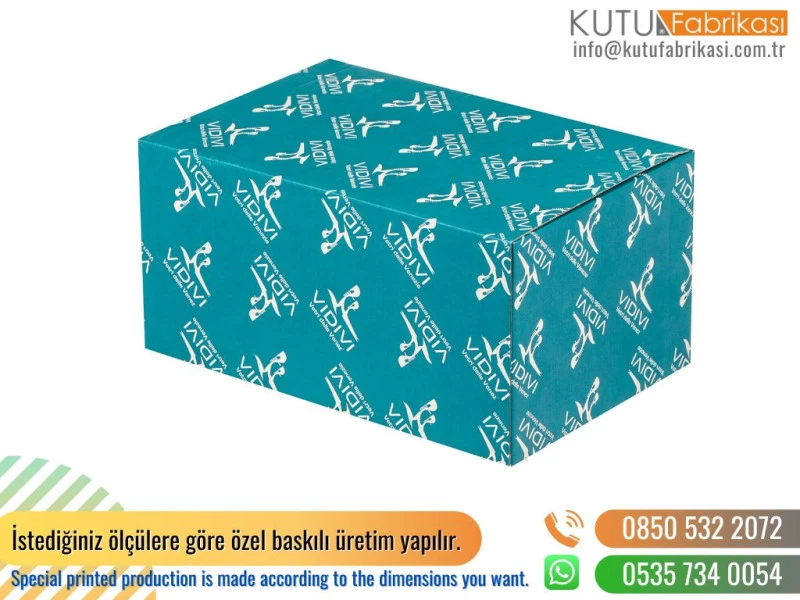

- Customizable Designs for Brand Identity

- Eco-Friendly Materials for Sustainable Practices

The Manufacturing Process: From Pulp to Package

To fully appreciate the quality of corrugated boxes, one must examine the meticulous manufacturing process. It begins with sourcing eco-friendly kraft paper, then moves on to the corrugation and lamination stages, where precision machinery transforms raw materials into the iconic corrugated structure. Next, cutting and scoring lines shape the boxes to specified dimensions, ensuring a snug fit for your products. Have you ever been curious about what goes into manufacturing a box that can safely house everything from luscious chocolates to high-tech electronics?

Demystifying Common Queries About Corrugated Boxes

How do corrugated boxes enhance brand identity?

Through customization options such as vibrant printing techniques, logos, and thematic branding, corrugated boxes become not just protective containers, but also a canvas for your brand's story.

What makes these boxes a sustainable packaging option?

Corrugated boxes are often made from recycled materials and are completely recyclable, reducing the carbon footprint and contributing to a circular economy.

Can corrugated boxes be designed for specific industry needs?

Yes, with advancements in technology, these boxes can be engineered with features such as moisture barriers, insulated linings, or anti-static properties, catering to specialized requirements from food packaging to sensitive electronic components.

Are there any limitations to the shapes and sizes available?

The versatility of the corrugated box is one of its greatest strengths, with custom die-cut boxes providing limitless shape and size options to perfectly fit any product imaginable.

Did you know that some corrugated boxes are now embedded with smart technology, allowing customers to track their shipments in real-time or gain additional product insights with a simple scan of a code? This leap in packaging technology not only assures the safe delivery of goods but also enhances the user experience manifold.

With options ranging from minimalist designs to elaborate creations, how will you design your next packaging project? Will you opt for the eco-friendly appeal of paper or lean towards the durability of plastic? Either way, the journey from concept to creation is seamless with the expertise of seasoned box manufacturers. To explore exquisite packaging solutions that reflect the caliber of your products, discover the craftsmanship of these boxes and the multitude of materials at your disposal.