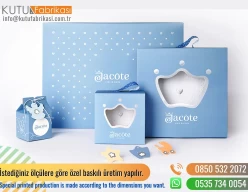

Printed Box

What are the types of printing houses?

1. Offset Printing House 2. Digital Printing House 3. Flexographic Printing House 4. Gravure Printing House 5. Screen Printing Press 6. Letterpress Printing House 7. Large Format Printing House 8 .3D Printing Press 9. Rotogravure Printing House 10. Heat Transfer Printing Machine

In which industries are boxes used?

Boxes range from food and beverage to electronics, cosmetics and more. It is one of the most versatile and widely used packaging materials today, used in a variety of industries and application areas.

Food and beverage:

Cans are a key component of the food and beverage industry, helping to preserve, store and transport perishable products such as fruit, vegetables, dairy and meat. They are also used to transport and protect items such as candy, snacks, and drinks. In addition to keeping food items safe, boxes can also be used to label products.

Electronics:

Electronic devices are delicate and delicate pieces of equipment and boxes can help keep them safe and secure during transportation. The right kind of box can ensure that electronic components reach their destination without being damaged or broken. The extra cushioning that boxes offer can also protect items from the elements and provide better protection against rough use.

Cosmetics and Pharmaceuticals:

Cosmetics and pharmaceutical industries require special attention when it comes to packaging, so boxes are often used. Boxes are a popular choice to ensure that products arrive at their destination in the same condition they were shipped. Boxes with dividers can be used to hold bottles.

Monochrome Printing:

Monochrome printing, also known as monochrome printing, is a type of printing that uses only one color of ink. This type of printing is used to achieve a simple, clean and clear look. Monochrome printing is often used on documents such as invoices and flyers, or tasks where one color stands out from the rest.

Multicolor Printing:

Multicolor printing, also known as 4-color printing, is a type of printing that uses four inks (cyan, magenta, yellow, and black) to create a spectrum of colors. . This type of printing is often used for business cards, brochures, catalogs, and other applications where a variety of colors are desired. Process colors are used to create the entire range of colors available, and only regular, high-quality ink will produce the desired result.

Photographic Printing:

Photographic printing is the process of creating prints from digital photographs or film negatives. This type of printing is used to produce large format prints or high quality images with a natural color palette. Prints can be made on a variety of photographic quality papers that are specially coated to achieve the desired image.

By what means are boxes exported?

Boxes can be exported in various ways, depending on the types of boxes being exported and how they will be used. Some common ways to export boxes include shipping by air, sea, road or rail, and shipping them by mail. Exporters often package and label their boxes to provide additional protection and ensure they arrive at their destination safely and quickly. Additionally, some exporters will use special services such as containerization or freight consolidation to maximize cost efficiency when exporting boxes.

The importance of graphic design in the printing house?

Graphic design is essential for printing successful projects. Graphic designers are responsible for creating visually appealing images while conveying the intended message. Graphic design is used to bring the desired outcome of a printed project to life using a variety of elements such as text, images, color and more. Graphic design must work in sync with other elements of the design, such as typography, layout and printing techniques.

When it comes to creating a successful printed piece, graphic design is key. He or she is responsible for conveying the project's message to readers, which can often mean the difference between success and failure. Graphic design also has the ability to add visual interest to any printed project, giving readers something to look at while making it easier to understand.

The use of typography is an important aspect of graphic design. It plays an important role in conveying the message and can be used to establish an overall tone for the project. Typography should be chosen carefully because the wrong font can easily make a project look messy and unprofessional. On the other hand, the right font can help attract readers and make the project stand out.

The use of color is another important aspect of graphic design. It can be used to set the mood of a printed piece and should be used strategically to emphasize message points. Colors should be chosen carefully, as too much color can be distracting and busy, while too little can make a printed piece look dull and boring.

Regular project is another important aspect of graphic design. It involves arranging elements such as text, images, and graphics in an orderly and visually appealing way. Good layout is also important to create balanced designs that make it easy for readers to follow.

Finally, printing techniques are also an important aspect of graphic design. It is important to choose the best printing techniques to ensure that the project turns out as desired. Common printing techniques include digital printing, offset printing, screen printing and more.

Graphic design is very important to create successful printed projects. It is responsible for bringing a project to life with visuals and conveying the desired message. Graphic design should be tailored to the needs of the project and include typography, color, layout and printing techniques. When done right, graphic design can help ensure that a project stands out from others and creates a lasting impact.

How are Printed box prices determined?

The most important factor in determining box prices is the quality of the materials used in the production process. Higher quality materials, such as premium cardboard and glossy lamination, tend to be more expensive than lower quality or different materials. Printing techniques also play a role in the cost of boxes. For example, offset printing tends to be more expensive than digital printing.

The size and quantity of the order will also play a role in determining the price of printed boxes. In general, the larger the order, the more affordable the unit cost. The complexity of the prints on the box is another factor to consider; For more complex designs, labor and materials will be more expensive.

Finally, prices may also vary depending on the supplier. Different companies will offer different prices based on their overhead, materials and printing techniques. While it's important to shop around for the best price, it's also important to ensure the quality of the printed boxes meets your needs. For detailed information, you can get support from our Contact section.

You can contact the manufacturer to have printed boxes manufactured. What information should be given to the company?

Printed boxes To have it done, you must provide the following information to the manufacturer:

• Detailed description of the packaged product. • Dimensions of the printed box, including length, width, and height. • Quantity of boxes you need and estimated delivery date. • The type of material and printing techniques you want to use. • Full picture with all the instructions you need. • The level of durability and protection you need. • Special processing requirements for the printed box.

If possible, it is also important to provide the manufacturer with a sample of the product you plan to put in the box. This will help them visualize the design and give them a better idea of the exact requirements. Additionally, be sure to communicate any other specifications or requirements you have for your boxes. This will help you make sure that the product is made to meet your expectations.

The importance of cardboard boxes in e-commerce?< br>

Printed cardboard boxes are of great importance in e-commerce because they serve many purposes, from storage to transportation to product promotion. Boxes can also be used to protect products during shipping and can be printed with logos and brand designs to improve customer experience. Boxes also play an important role in marketing campaigns as they are often used to showcase products and create an attractive visual presentation for retail stores. The use of parcels in the e-commerce industry is essential to ensure safe delivery of products, to provide positive experiences to customers and to protect the products inside.