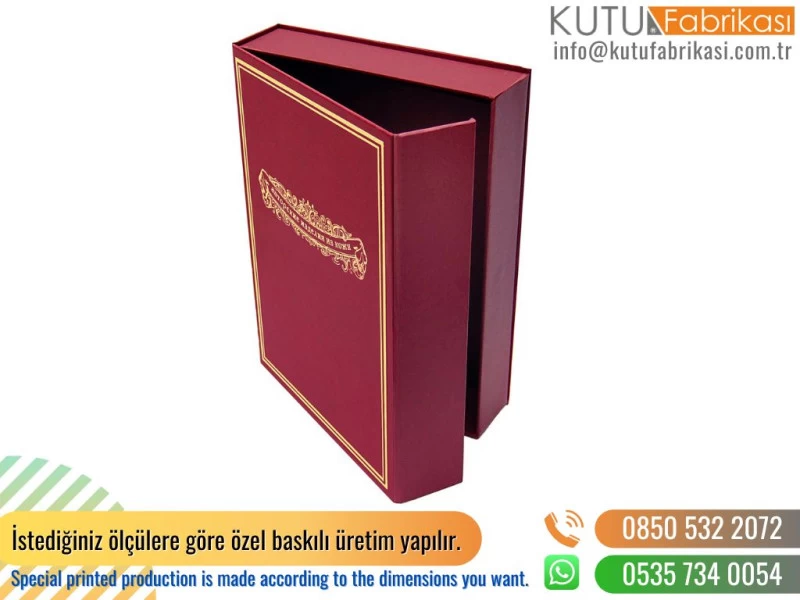

Hardcover Box Manufacturer

Unveiling the Craftsmanship Behind Hardcover Box Manufacturing

In the domain of packaging, the hardcover box stands as a paragon of durability and elegance. Tailoring packaging to encapsulate diverse products ranging from pastries to pizzas and cosmetics to jewelry, box manufacturers harness a variety of materials to create solutions that not only protect but also amplify the essence of the items within. The choice of paper, cardboard, velvet, metal, wood, plastic, or PVC can profoundly influence both the presentation and preservation of your product, making it crucial to select the optimal material that aligns with the item's needs and the brand's image.

Materials and Design: Piecing Together the Perfect Hardcover Box

Selecting the right material for your product can be a transformative process. Does the sleek feel of laminated cardboard convey the premium quality of your gourmet chocolates, or does the rustic charm of wood better suit the artisanal nature of your baked goods? As manufacturers adept in global exportation, options for packaging materials are plentiful and can meet the specifications and cultural nuances of various countries.

The Benefits of Choosing the Right Packaging

- Improved Product Safety and Integrity

- Elevated Brand Perception and Value

- Material Versatility to Suit Diverse Industries

- Eco-Friendly Options for Sustainability

Consider the journey that a high-end piece of jewelry takes from the maker to the customer. The protection offered by a durable hardcover box is as pivotal as the luxurious unveiling experience it facilitates. This is why paying attention to both form and function is essential in creating packaging that not only serves its primary purpose but also tells a story, enhancing the consumer's overall experience.

Addressing the Curious Minds: Common Questions About Hardcover Box Manufacturing

What innovative features can be incorporated into a hardcover box design?

Incorporating elements like magnetic closures, custom inserts, or even smart tech such as NFC tags can create an interactive experience, making the unboxing as memorable as the product itself.

How does material choice affect the cost-effectiveness of box manufacturing?

Material selection is crucial in balancing quality with cost. Options like paperboard offer economical yet sturdy choices, whereas materials like velvet or metal may increase costs but offer a heightened sense of luxury.

Can hardcover boxes be designed for environmental sustainability?

Absolutely, the use of recyclable materials and soy-based inks are just some ways box manufacturing is evolving to meet ecological standards without compromising on strength or aesthetic appeal.

What considerations should be made for the global export of hardcover boxes?

Factors such as the durability to withstand long shipping routes, language-specific labeling, and cultural design preferences all play a part in successfully exporting hardcover boxes to international markets.

Fascinatingly, the world of box manufacturing has even seen packaging that changes color with temperature, adding an extra layer of interaction and excitement for the end-user. With this in mind, what innovative addition would you choose to enhance the functionality and intrigue of your hardcover box?

The Taste Box plays a big role, especially in the sale of luxury products. It is an ideal solution for promotions and promotions in the marketing of products. Thanks to its durability, it can provide long-term use. Applications such as embossing, printing and gilding can be made with prints based on the quality of the materials. In addition, the result produced by the workmanship during production also regulates the quality of the drafting box.

Printed cardboard boxes have become almost the most important element of environmentally friendly packaging. It is especially preferred to ensure the regular, safe and practical transportation of small and light measures. However, the illustrated cardboard boxes are also an effective use of advertising for many products. There are also very special and high expectation models, usually with low temperatures and versatile use. Printed cardboard boxes can be easily recycled as waste material and used to prevent garbage. Printed boxes are a great tool to give your customer brand recognition. The fact that they are printed according to various sectors such as clothing products, cosmetics and chocolate increases the importance of removing the buyer product once. Most companies appreciate the contribution of brands to evaluate the review box print. Lightweight, with ample workspace and businesses, cardboard boxes are an excellent choice for commercial purposes.

Paper, binding cloth, leather, coated paper, gilding cellophane etc. The process of sticking materials on materials such as cardboard and cardboard with glue is called "drawing".

Frame boxes are made of materials such as coated paper, cardboard, velvet or hard cardboard.

Yes, we are able to produce draft boxes in different sizes. They can be customized depending on our customers' request. We offer you options such as various accessories, ribbons, metal accessories, sponge separators.

Tassel boxes are generally used in the packaging of souvenirs, jewelry, perfume, cosmetics, wine or other luxury products. They can also be preferred for special events, weddings or corporate gift wrapping.

Design boxes offer elegance, durability and a luxurious look together. While protecting your products, they also elevate your brand image. They are an impressive option for a special gift or product presentation.

We can customize draft boxes in a variety of ways. Options such as printing, different colors, logos, embossing or embellishments made with different materials are available.

You can contact us for your order and state your needs and preferences. We share details such as size, material, design. Then we create a design for you and submit it to your approval. After receiving approval, we move on to the production process and deliver the desired number of drafting boxes to you.

The minimum order quantity is 100 pieces, it can change depending on your demands. When you send us your needs and requests, we can determine the minimum order quantity that suits you best.

The draft box production time varies depending on the size and complexity of the order. Typically, production time takes between 2 and 4 weeks from design approval.

The price of draft boxes is determined by the dimensions of the box, material selection, customization accessory details and the order quantity. It is important to provide us with the details so that we can offer you a bespoke price quote.

It is important to choose a design that reflects the characteristics of your brand or products in the design of the draft box. In addition to being visually attractive, it is also necessary to pay attention to ease of use.

We securely pack and ship your draft boxes. We use suitable packaging materials to protect the boxes and prevent them from being damaged.

We use high-quality materials and work meticulously with our experienced specialists to produce quality cardboard boxes. We take care to offer the best quality to our customers by passing our products through quality control processes.

Yes, it is possible to recycle cardboard boxes. Since it is cardboard or cardboard material, it is easy to recycle it in waste management processes.

Cardboard Plastered Box is a box made of cardboard material, covered with a plastering technique to protect the contents and ensure safe transportation.